You know what they say: bigger is always better. Turns out that's exactly the case for front splitters. I recently got tasked with a project for a good friend of mine - find out the best splitter size. I currently have a 2" front splitter on my AP1 and it worked great when the car was dual purpose. But now that it is a dedicated track only car, I thought 2" wasn't going to cut it. After further research that's exactly the case.

To give a little more background before I get to the nitty gritty stuff, the main purpose is to find the best splitter that complies with NASA Time Trial rules (specifically TT4 in this case). This makes it easy on my end since they only allow perfectly flat splitters and it can only extend 4" past the body. I do plan on doing some research on how much benefit spats and winglets do, but for the time being the variable in question here is size.

First thing I did was scan my front end. I only show my bumper here, but I have a scan of most of the car at this point. I would have loved to do the whole thing, but it takes about a half hour to just analyze the bumper and it's dangerously close to crashing my graphics card. Here are some shots of my model:

What I did was initially run my CFD model with just the bumper by itself. These are the numbers that I am using as my baseline. Don't take stock into the numbers themselves, but only the differences. Once that was achieved I took measurements at 2", 2.5", 3", 3.5", and finally 4" past the bumper. The thickness of the splitter is kept constant throughout.

Here is a cool shot I took showing the air path and surface plot on top of the splitter. You can see the highest pressure is right in front of the bumper! I tried to show the trajectory around the entire bumper but my computer crashed! I can really only render small pieces at a time.

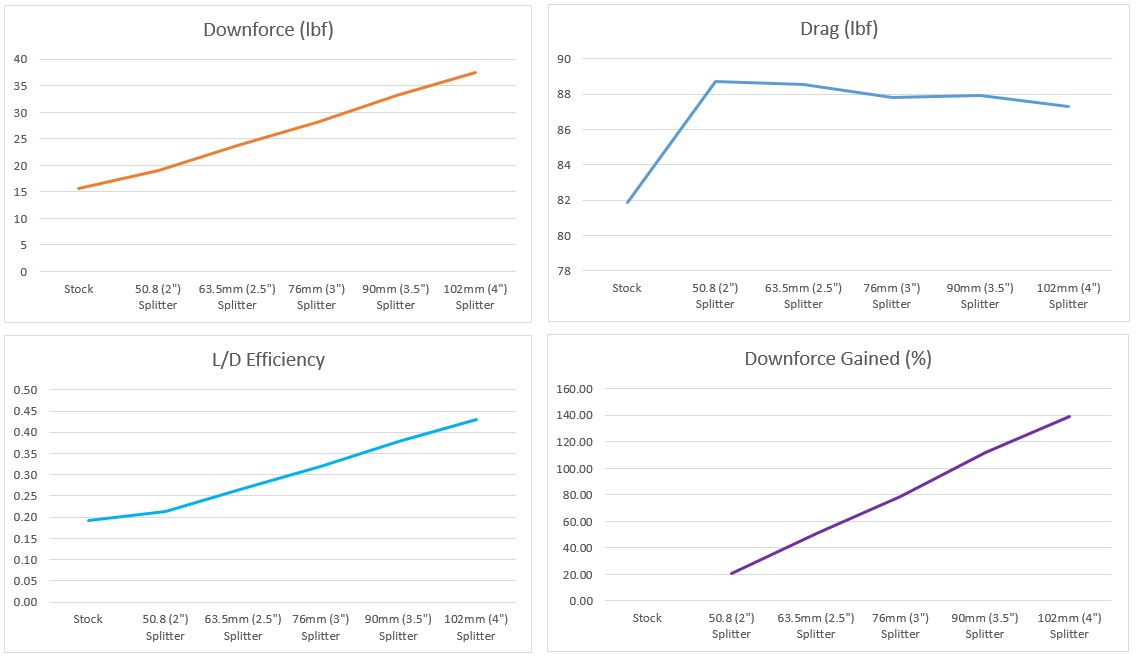

Now the results are displayed below. As you can see, as the size of the splitter is increased so too is the downforce. The good part is the added drag is pretty much negligible as you increase size, so the only downsides are a little bit extra weight, and it's much harder to get the car on the trailer. What I plan on doing is creating quick disconnect brackets for my splitter, so I don't have to touch the front bumper to take it off. This will allow me to keep it off the car while trailoring and put it on the car once I am at the track in only a few minutes.

4" splitter here I come!